At TCT ASIA 2025, IMT made a groundbreaking appearance under the theme "Zero-Waste Process + Full-Cycle Carbon Reduction," showcasing core technologies to discuss with global industry pioneers in exploring cutting-edge trends of 3D printing technology.

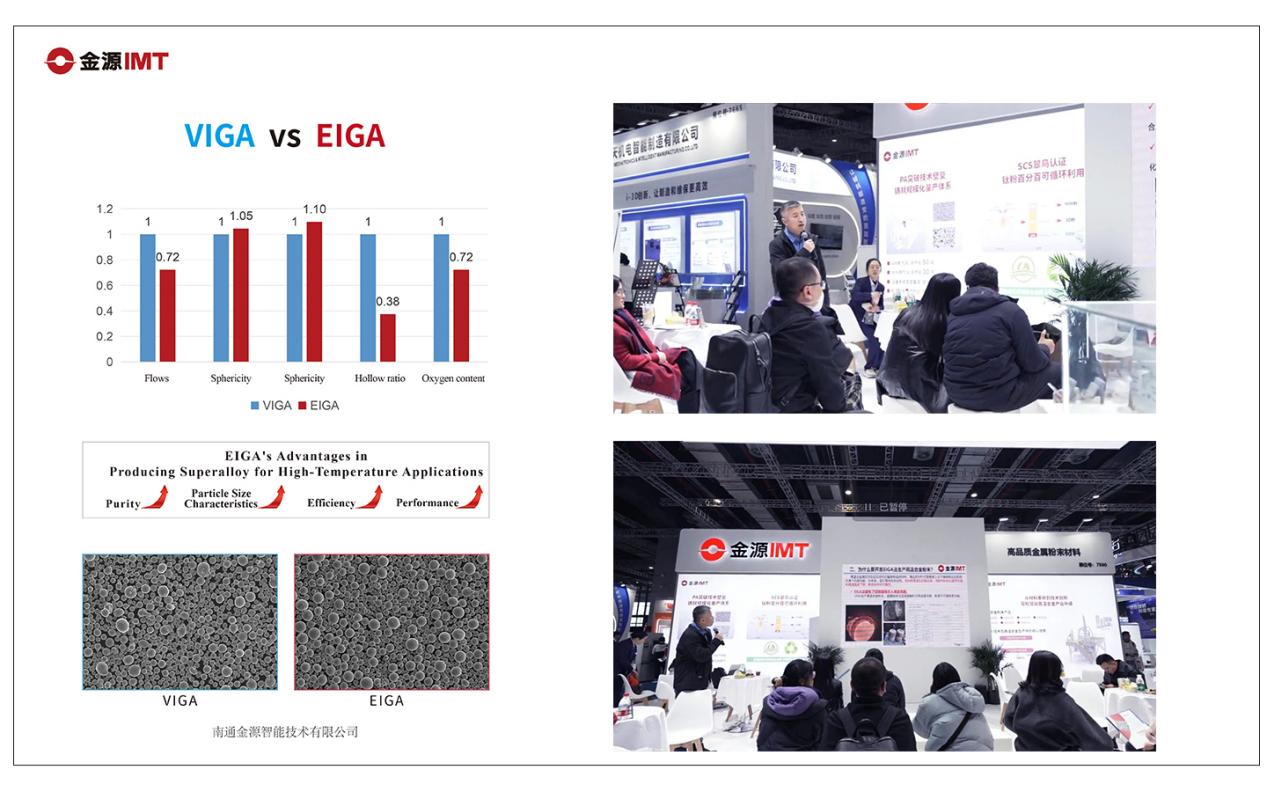

EIGA technology innovates high temperature alloy production process

Having mastered the EIGA (Electrode Induction Gas Atomization) process for producing superalloy powders, IMT achieves precise composition control and superior physical properties. These powders demonstrate stable applications in aerospace turbine blades, energy sector gas turbines, nuclear power core components, and automotive turbocharging systems, imparting exceptional creep resistance, oxidation resistance, and wear corrosion resistance to components operating under extreme high-temperature, high-pressure, and corrosive environments. This significantly extends critical component lifespans while reducing maintenance costs. On-site technical presentations highlighted IMT’s breakthrough innovations in EIGA-based superalloy production.

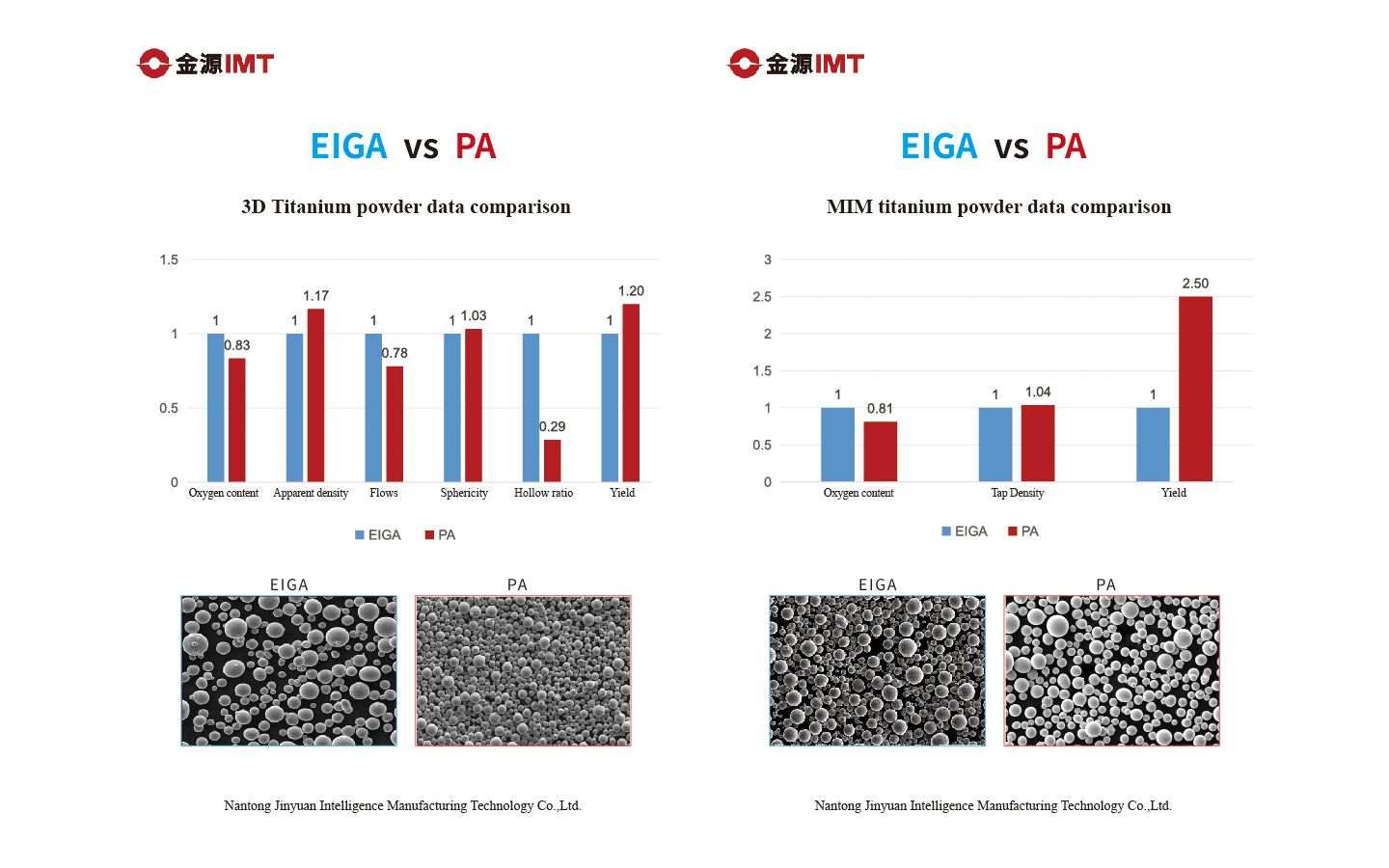

Technological breakthroughs, production capacity surge, titanium powder production breakthrough

Addressing current industry challenges where 3C manufacturers face tight MIM titanium powder supply and technical bottlenecks in precision component fabrication via 3D printing, IMT has independently developed PA (Plasma Atomization) powder production systems. The company has achieved thousand-ton-scale production capacity for both 3D printing titanium powders and MIM powders. PA titanium powders marked advantages over traditional EIGA processes in hollow rate, oxygen content, and yield rate etc..

Zero waste process + full-cycle carbon reduction to build a green manufacturing system

Through proprietary Hydrogenation-dehydrogenation (HDH) technology, IMT realizes 100% material conversion efficiency from raw materials to titanium alloy powders, implementing low-carbon manufacturing principles at the production source and achieving genuine zero-waste operations. To establish new environmental benchmarks, IMT has secured SCS Global Certification (formerly Scientific Certification Systems) for its titanium powders.

Propelled by robust technological capabilities and uncompromising quality standards, IMT solidifies its leadership in metal powder materials for 3D printing and 3C applications. Through continuous R&D and production innovation, the company injects transformative momentum into industrial advancement.

Propelled by robust technological capabilities and uncompromising quality standards, IMT solidifies its leadership in metal powder materials for 3D printing and 3C applications. Through continuous R&D and production innovation, the company injects transformative momentum into industrial advancement.